How To Set Timing On Lt1 Motor

Chevrolet's LT1 engine family evokes all kinds of emotions among Bow-Tie guys.

Those in the know remember the original 350 cubic-inch LT1 introduced in 1970 was a real powerhouse with a hot mechanical cam and 370 horsepower on tap from the factory.

It was the terminal actually hot Chevy modest-block ever washed, with the exception being the loftier-revving Trans Am-inspired 302 c.i.d. Z28 in 1969. The 350 LT1 rocked. In the years to follow, the LT1 lost adrenaline to tough federal emission standards and higher auto insurance rates. By the mid-1970s, the honeymoon was over.

As the 1980s unfolded, performance became more in manner, with Chevrolet leading the pack in that age-old battle with Ford. Those fuel-injected 5.0L Mustangs were a force to be reckoned with and Chevrolet was paying shut attention. Chevrolet brought us Cross-Fire injection in 1982, which didn't print anyone. In the mid-1980s, GM brought u.s. Tuned Port Injection (TPI), which was tunable and certainly a smashing success. TPI endured and remained an industry standard for years.

The redesigned Gen. II LT1 Chevrolet small-block (L98) introduced in the 1992 Corvette was an updated version of the time-proven modest-block first introduced in 1955 with its share of interesting refinements—some quite controversial.

The cam-driven water pump with opposite-flow cooling and OptiSpark ignition system were revolutionary. Nonetheless, OptiSpark has always been problematic. It has as well been refined and improved by both GM and the aftermarket. MSD, as 1 example, offers a terrific OptiSpark replacement distributor as does Accel.

You can even retrofit the LT1/LT4 with a cool LS coil-on-plug ignition system and eliminate OptiSpark entirely.

The Lingenfelter Functioning Engineering curl-on-plug conversion solves the OptiSpark ignition issues. The LT1 coil-on-plug converters with adjustable retard and intelligent rev limiter notwithstanding apply the optical module in the OptiSpark distributor, but without loftier-voltage passing through it.

Within the LTCC packet, you take the LTCC module and the harness with eight leads, each with a Weatherpack connector and ground wire, a pigtail connector, and four non-harnessed wires. At that place are plenty of OptiSpark ignition choices to run across your ignition needs.

The LT1 engine in displacements of 265 and 350 cubic inches was employed in a number of General Motors vehicles including the 1992-'96 Corvette, 1993-'97 Camaro and Firebird, 1994-'96 Chevy Caprice and Impala, Buick Roadmaster, and the beasty Cadillac Fleetwood luxury rides.

What fabricated the LT1 series and so successful was greater amounts of power by yielding a broader torque curve enabling total-sized luxury cars to advance aggressively to speed onto the state highway. In performance vehicles like the Impala SS, Camaro, and Firebird, it roared out of traffic lights in an inspiring fashion. Information technology rocked. What's more than, there was so much y'all could practise with it in terms of performance.

Let'southward Get to It

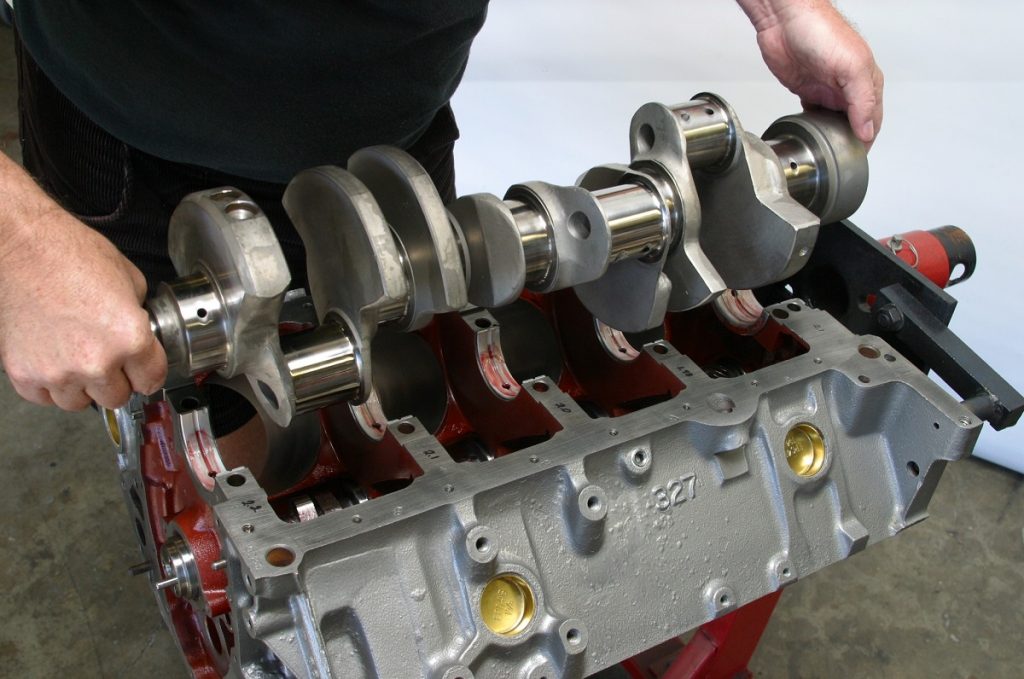

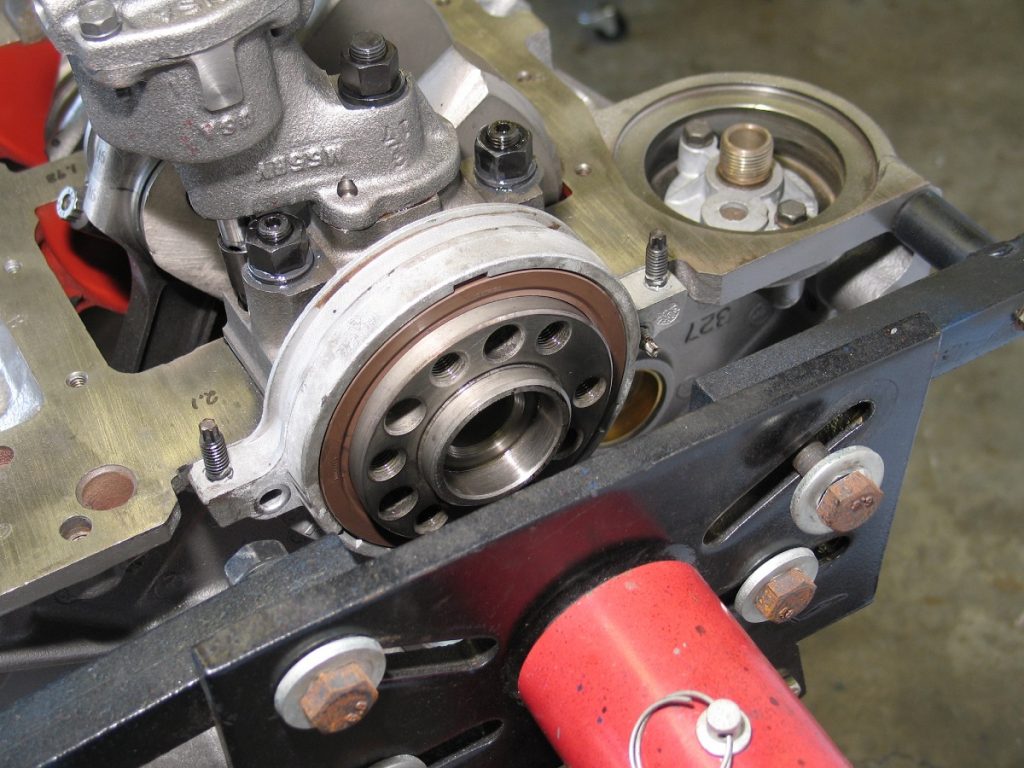

Nosotros're working with a 1996 vintage LT1 block, identifiable by its "327" visible in the block and a casting number of #10125327 for the 5.7L V8 with a 4.000-inch bore.

This block casting was used from 1992-97. There's only one other LT1 block casting numbered #10168588 for the smaller bore (3.736-inches) L99 4.3L V8 (265 c.i.d.), which was available in the Caprice as the base V8. What we're near to practise here applies to both the 350 and the 265.

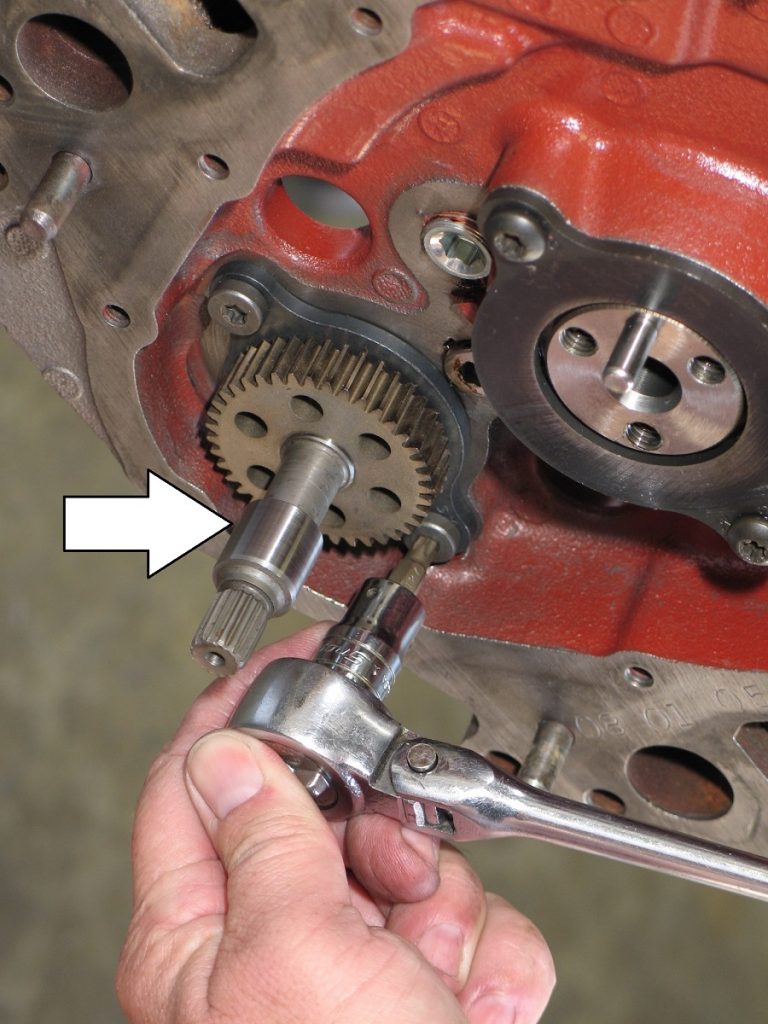

What makes the 1992-97 LT1 block dissimilar from the traditional Chevy small-scale-cake is what it has—and what it doesn't have. Information technology doesn't have an adaptation for a benefactor like well-nigh Chevy minor blocks. Instead, it has an oil pump bulldoze stuffed in the block in back secured by a single bolt. The LT1 cake actually is an entirely different block and needs to be treated as such. Some items are interchangeable—some are non. Intake manifolds, as one example, are not.

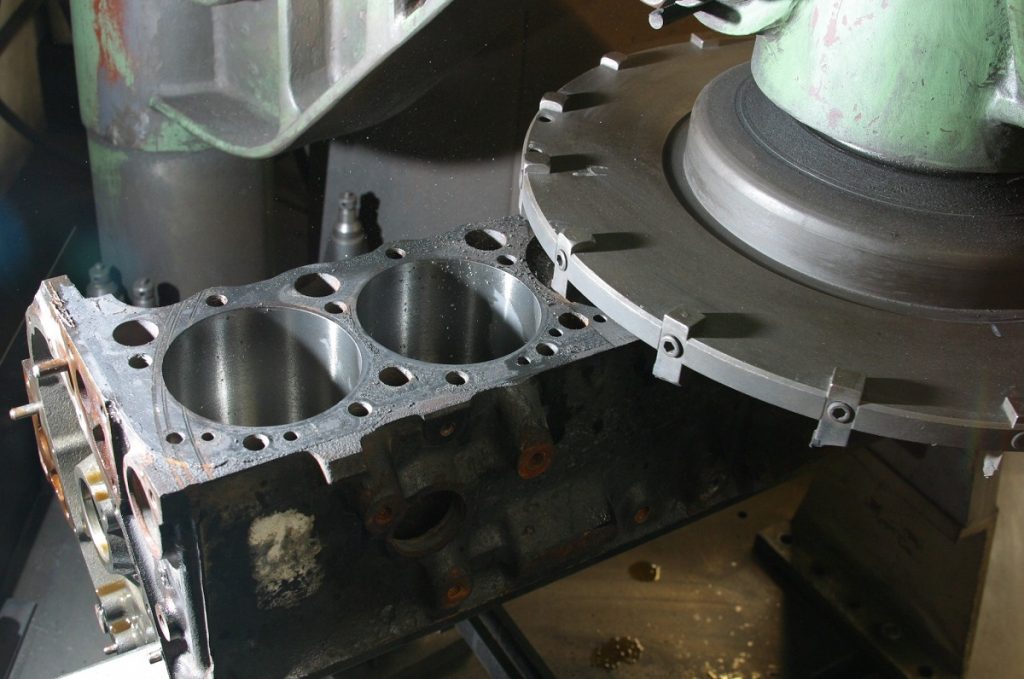

50&R Engines of Los Angeles, CA provided us with a standard bore LT1 5.7L block bored and honed .030-inch oversize (4.030"). The cake has been professionally cleaned, prepped and machined for this build attempt. This cake has been line-honed, bored and honed, and the decks cut to give us a clean, crisp, ready to assemble short-block.

When Chevrolet introduced the 300-hp LT1 (Gen. II) fuel-injected small-scale-block in 1992, it was a more-advanced 350 c.i.d. Chevrolet V-8 small-scale-cake, which was a cut in a higher place the Tuned Port Injection pocket-size-cake showtime introduced in 1984.

TPI gear up a new benchmark for operation when it debuted in the all-new 1984 Corvette and the white-hot 1985 IROC-Z Camaro. It offered incredible performance coupled with something unheard of with loftier-performance V8 engines of the era—fuel economy. Port fuel injection coupled with aggressive roller tappet technology made the TPI a quantum leap in performance. No one did it better than Chevrolet.

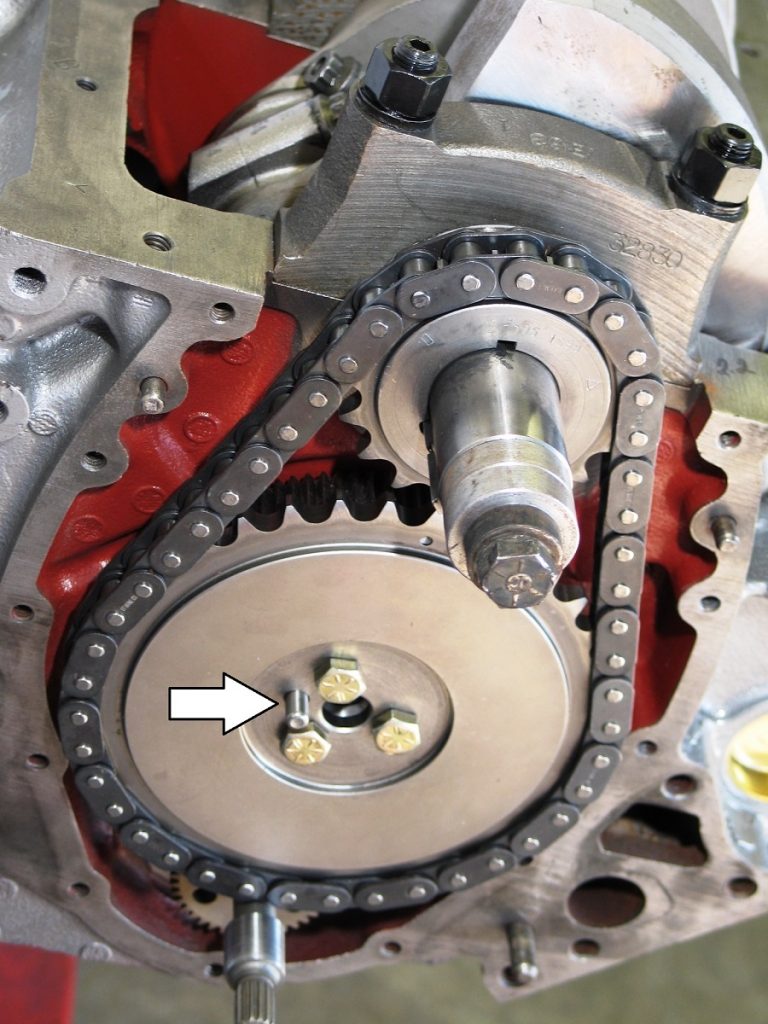

The new Chevy Gen. II LT1 took TPI to the adjacent level with features that made it a vastly improved minor block. The objective was reduced emissions and greater amounts of ability. GM did abroad with the chugalug-driven water pump and rear HEI distributor—replaced with a camshaft-driven, contrary-flow water pump, and OptiSpark ignition.

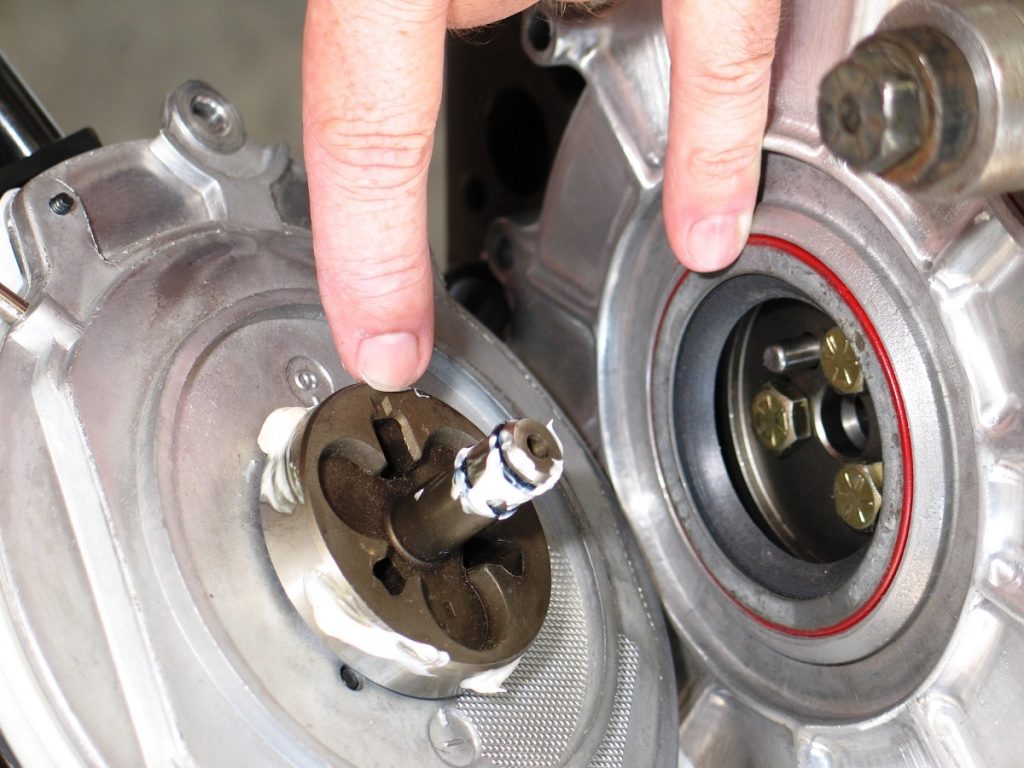

OptiSpark was a pancake-style, light-triggered electronic distributor located beneath the cam-driven water pump. At that place were two types of OptiSpark ignition systems. There was the unvented (1992-'94) and vented (1995-'97). Y'all will want the vented OptiSpark.

A reverse-flow cooling system was conceived to recoup for the much higher 10.5:i compression ratio long with leaner fuel mixtures to clean up emissions. Contrary-flow became the standard all across the auto manufacture.

Chevrolet'southward selling point in technology would also be the Gen. II's undoing. OptiSpark was plagued with reliability problems that troubled Corvettes, Camaros, and other GM models in the 1990s. Oil leaks effectually the water pump bulldoze not merely spotted driveways, merely Chevrolet'due south not bad reputation for reliability and performance. Between GM's efforts, and the aftermarket's, these problems aren't as bad as they used to be. However, they have to be a priority for your LT1 build. Your job is to build a trouble-complimentary LT1/LT4.

Despite the LT1's engineering shortcomings upwards front, it was a terrific manufacturing plant small block sporting a nodular iron creepo, powdered metal "croaky" connecting rods, and hypereutectic pistons. In 1992, the LT1 yielded 300 hp. By the cease of production in 1997, it was making 330 mill ponies in the powerful LT4.

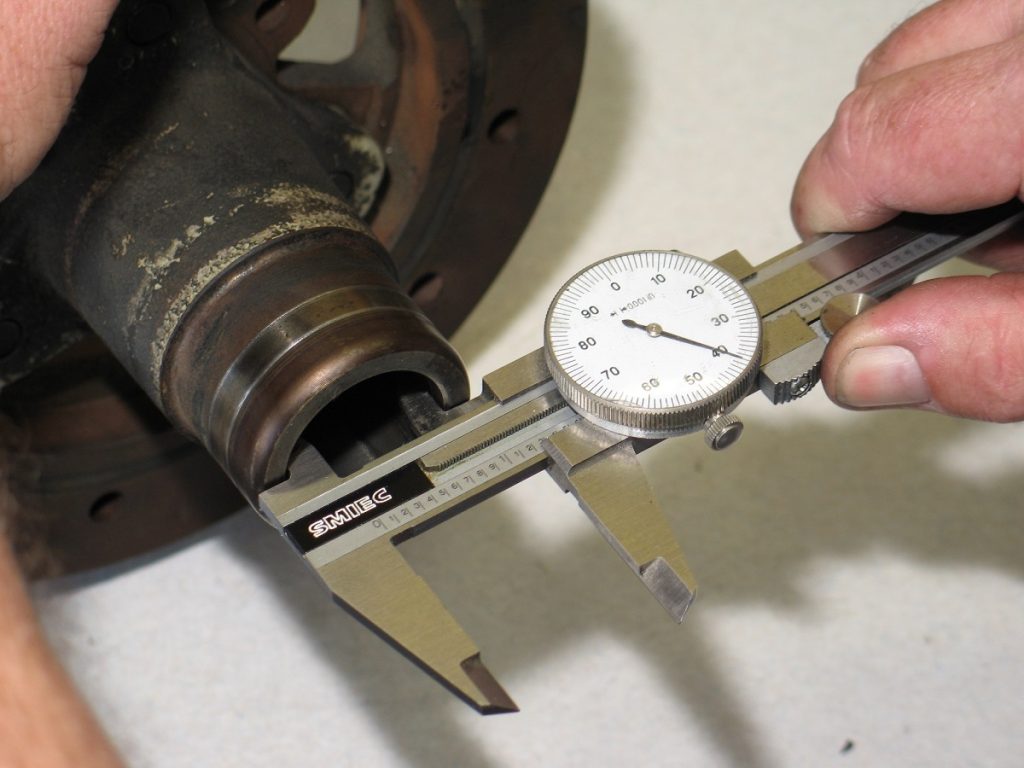

GM made two types of Gen Two LT1 blocks in the 1990s—2-bolt main and four-bolt main. Four-bolt primary versions were factory installed in Corvettes by and large. Yet—wait to meet the four-bolt main LT block in about anything built in the 1990s. Because they both have the aforementioned casting number of "327" they are impossible to confirm without removing the oil pan.

Although nigh 1992-97 LT1 engines had aluminum heads, it is of import to call up there are LT1s with iron heads institute in full-size GM sedans of the era. The Caprices had similar-looking 265 c.i.d. small-blocks (L99) that resemble the LT1. These engines are easily identified by their smaller 3.740-inch bores and iron heads. Don't accidentally choice ane of these up for your LT1 build project.

When we decided to build a Gen. II LT1 383 stroker, nosotros understood it was a meaning turning point in the minor-block Chevy'due south 37-yr history. It would also be the small-block Chevrolet's curtain call—the cease of a very successful design run that would end on a mass scale at the 42-twelvemonth marker.

Truth is, Chevrolet never really stopped building small blocks because they're still available every bit crate engines from Chevrolet Performance. And if you're really into numbers, Chevy has congenital well in excess of 90 million pocket-size blocks since 1955. It is hands the well-nigh mutual V8 engine ever produced and distributed around the world.

Nosotros're building a solid, reliable LT1 383 c.i.d. stroker to see simply how much power we can make from GM's LT1 five.7L engine.

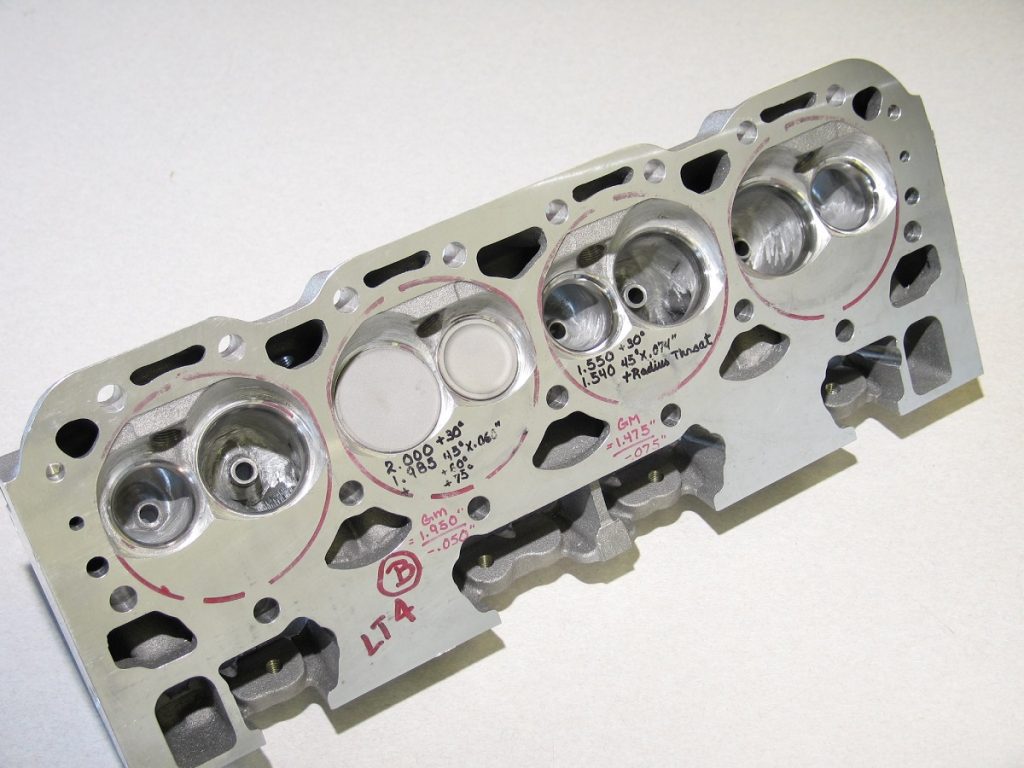

Mark Jeffrey of Trans Am Racing in Gardena, CA volunteered to build our LT1 turned LT4, with the objective being 450 hp, with a broad, stump-pulling torque curve. Mark had Air Flow Research cylinder heads in mind for our LT1 build forth with an aggressive street cam package that would be skillful for both the commute and racetrack.

However, the machine'southward possessor wanted a stealthy—stock in advent, using as many genuine GM parts as we could muster on the surface. We copped LT4 heads and consecration from Chevrolet Functioning, which were available at the time this engine was congenital in 2005. Thank you to a 383 c.i.d. stroker kit from Coast Loftier Performance, a hot roller cam kit from COMP Cams, and custom port and bowl work from Mark Jeffrey at Trans Am Racing, we were able to take a 300-horse LT1 and make 475 hp. Imagine what you could do with AFR heads— which would push it way over 500 horsepower.

Let's go started.

LT1/LT4 Cylinder Head Types

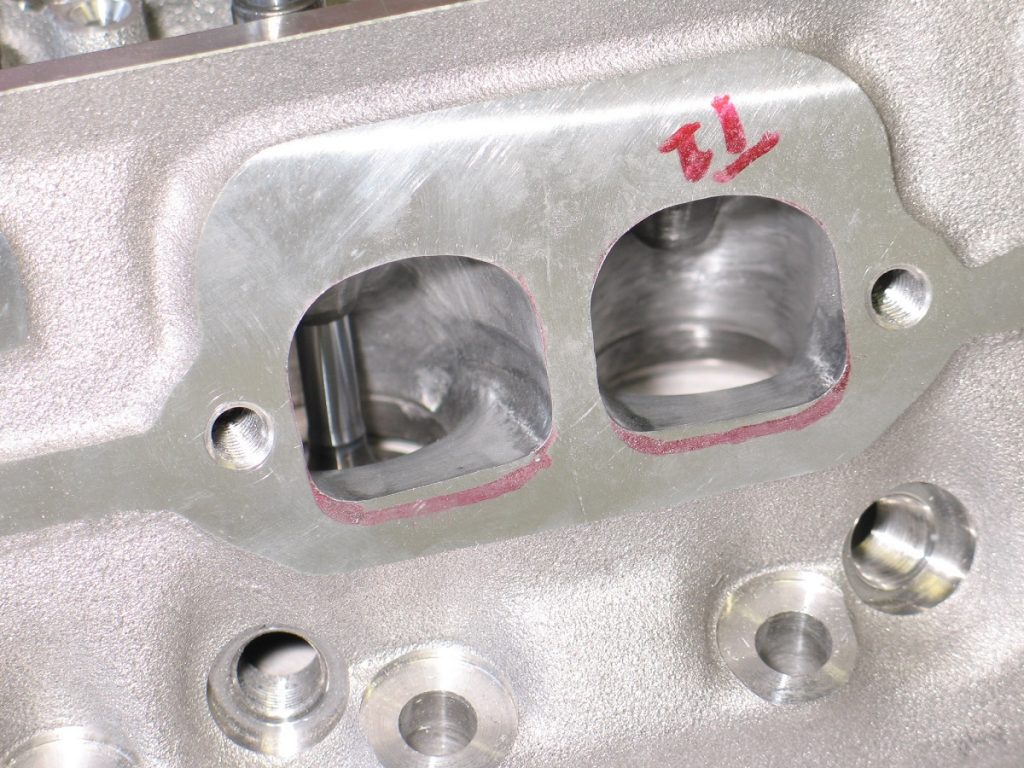

GM produced a number of LT1 cylinder heads during the 1990s. Here'southward how they stack up. Be conscientious when shopping for these heads—there were viii different aluminum cylinder head castings produced for the LT1/LT4. LT1/LT4 heads utilise track-style cocky-adjustment rocker arms similar to the LS.

What's more, the valve covers employ bolts through the center of the comprehend unlike perimeter style bolts on the small block Chevy and fifty-fifty early on LS engines. Keep squarely in mind LT1 heads and intake do not interchange with LT4. If yous have LT4 heads, you must employ the LT4 intake. What makes the LT4 head and induction better is improved port flow and greater compression.

LT1/LT4 Aluminum Caput Identification

How To Set Timing On Lt1 Motor,

Source: https://www.onallcylinders.com/2020/09/02/the-last-small-block-chevys-gen-ii-lt1-lt4-1992-97/

Posted by: wickthistalre.blogspot.com

0 Response to "How To Set Timing On Lt1 Motor"

Post a Comment